Phase IV

Compression Test

May/21/2025

As part of resatring the season a compression test is part of the check list. I'm getting a range between 95 on 2 and 4 and 105 on 1 and 3. Not perfect but I'll take it.

Checklist for Season 2025 Prep

Apr/26/2025

It's that time of the year when we take the Jeep out of hibernation using our seasonal checklist.

Prep for 2024 Summer Season

Jun/14/2024

It's time to wake up the Jeep from its long winter knap and prepare it for the summer events.

Winter Canvas Top

Sep/11/2022

I added a Winter Top. Living in Seattle you can be sure it will rain on your Parade!

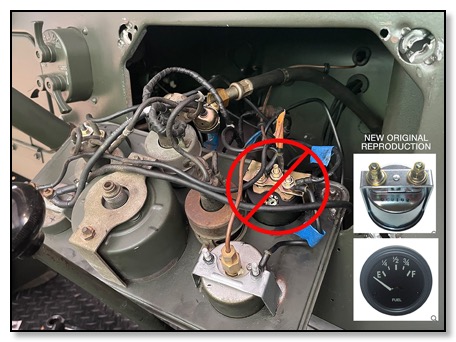

New Fuel Gauge

Jul/08/2022

There was a problem with my fuel gauge. It bounced around or just didn't work. It turned out to be a malfunctioning gauge not a wiring isssue. I replaced it with a better quality one form Kaiser Willys.

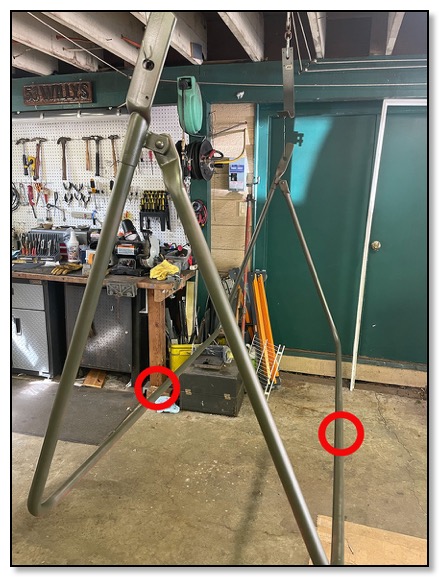

Bow for Winter Top

Jun/25/2022

When I ordered the Bow for the canvas Winter Top I had the vendor cut in it half to save a bundle on shipping. All I had to do was weld it back together.

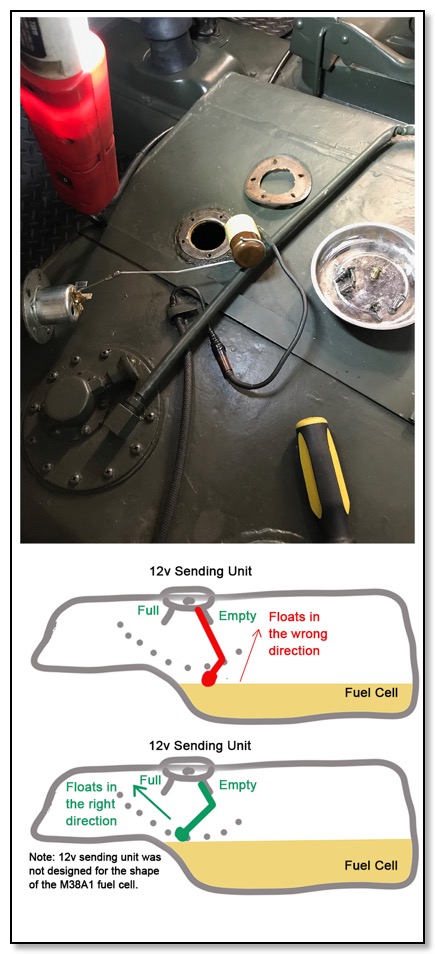

Fixed Fuel Gauge

Jun/22/2019

Fixed the fuel gauge. The after market 12v sending unit was not adjusted correctly. The float moved too far past the empty position and then when fuel was added it would float up the wrong way causing the gauge to read empty all the time. Also, the 12v version of the sending unit was not designed for the shape of the M38A1 tank. When it shows empty there is another gallon remaining.

Prep for Season 2019

Apr/22/2019

It's time to bring the Jeep out of its winter hibernation. I reinstalled the seats after being stored in a warm dry space for the winter. I also put a little Marvel Mystery Oil in each cylinder to lub those dry cylinder walls. It's up on blocks to check for leaks, and check the torque a few bolts. The battery has been on a trickle charge all winter.

Faulty Oil Pressure Gauge

Jul/09/2018

The oil pressure gauge was showing very low pressure 1 to 2 PSI at hot idle. After checking it with an external mechanical pressure gauge it was confirmed to be a bad gauge — a much easier fix than a bad oil pump or main crankshaft bearings!

Ethanol Free Gas

Jun/29/2018

Installed the seat back in the Jeep. We took them out and stored them indoors. The garage was too damp and the canvas covers turned out to be a wonerful breeding ground for mold (see Februay 18)

Seats Back In

May/23/2018

Covering the Jeep for the winter protects the paint but in my high humidity garage it becomes the perfect environment for mold on the canvas seats. After cleaning off the mold and treating the seats with a mixture of alcohol and water, we removed the seats and moved them to indoor storage.

Storage Mold

Feb/18/2018

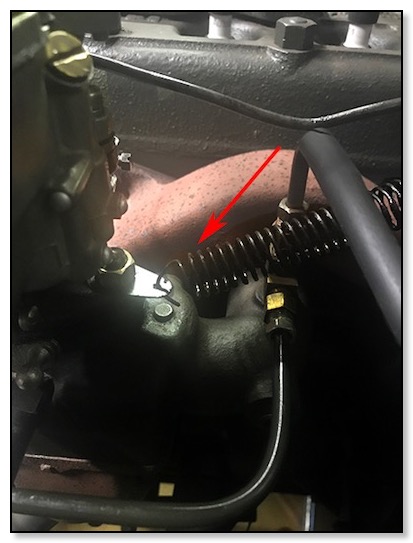

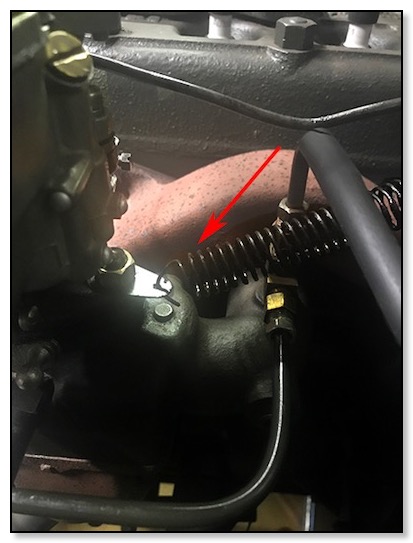

The previous owner rigged a makeshift throttle return spring setup. It was not period correct and often failed to return to the correct idle position. We installed the correct NOS configuration. It functions properly now.

Throttle Return Spring

Jun/16/2017

The previous owner rigged a makeshift throttle return spring setup. It was not period correct and often failed to return to the correct idle position. We installed the correct NOS configuration. It functions properly now.

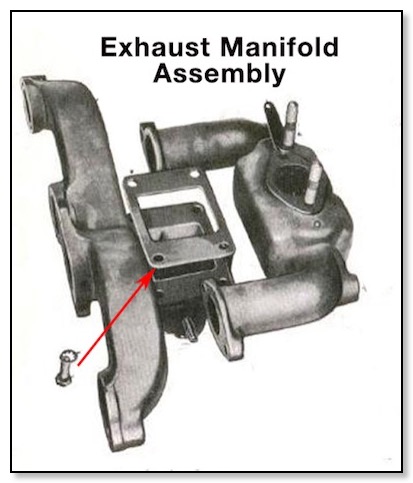

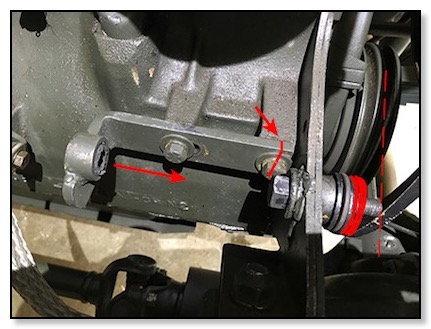

Finally, No Exhaust Leak!

Jun/09/2017

After fixing the exhaust pipe and flange alignment we discovered the major exhaust leak. It turned out to be a missing bolt on the lower exhaust manifold assembly. Don’t know if we missed it on the rebuild or it worked it’s way out, probably the former!

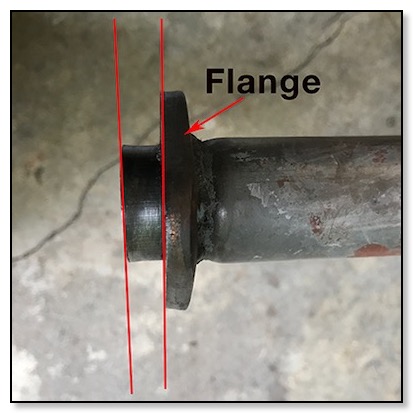

Close but no cigar!

Jun/09/2017

The problem with the exhaust alignment turned out to be a misaligned exhaust flange on the down pipe from the manifold. Just an eight of an inch can through the hole assembly off requiring too much force on the joints. After replacing the pipe everything lined up correctly.

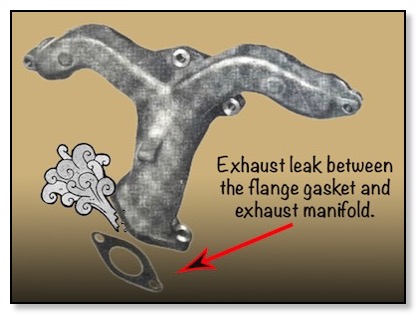

Exhaust Leak Part II

May/21/2017

Fixed (we hope) a nagging exhaust leak at the connection of the tailpipe flange to exhaust manifold. Because we have attempted to fix this before with short term success, we’re afraid it may be caused by misalignment of the exhaust assembly. We really had to put a lot of force on the connection to get all the bolts to line up. We replaced the gasket and used Permatex Ultra Copper. Time will tell.

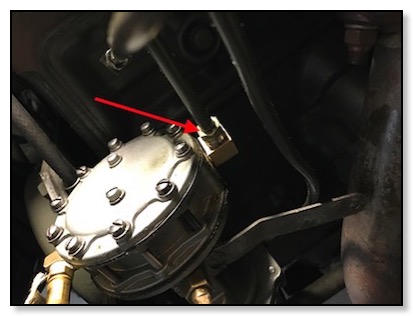

Fixed Small Fuel Leak

May/02/2017

After installing a new fuel to carburetor line we had to fix a small fuel leak at the fuel pump.

Generator and Altenator

Apr/28/2017

The generator and new regulator are back on, charging strong! We took the Jeep out for a test drive. After returning we noticed a little fuel leaking from the fitting at the fuel pump. This is just part of the tweaking we have to do to get it “ship shape” and ready for this season’s parades and shows.

Generator Allignment

Apr/17/2017

In working with the 12 volt conversion generator we noticed that the pulley was not properly aligned with the other pulleys. It was about 1/2 inch short. To fix the problem we hand to trim the generator bracket, relocate the bolt wholes and add a few more washers for spacers.

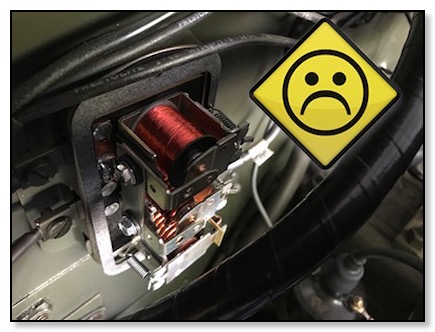

Regulator Fail!

Apr/16/2017

After rebuilding the generator and reinstalling it we watched the gauge jump to 14 volts as the refurbished generator got back to work. We drove the Jeep a few times around the block and parked it. About 15 minutes later we noticed smoke coming from the engine bay. It was the generator bellowing out smoke with that terrible odor of burnt wiring. It turns out we had a regulator failure and it shorted out the generator, destroying the armature. Restoration is not a perfect road!

* Note:

We may have been the cause of the regulator failure!

[See Lessons Learned]

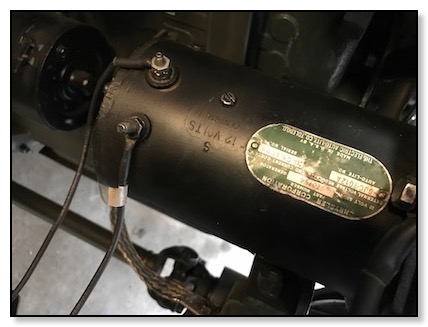

Rebuilding the Generator

Apr/02/2017

The Jeep was making a squealing sound after driving it for a short time. It sounded like a failing bearing. We suspect the generator so we rebuild it.

* Note: This turned out to be a misdiagnosis. [See Learning Curve]

Replaced Solex Carb

Oct/10/2016

We replaced the loaner Solex Carburetor with the rebuilt period correct Carter WO Carburetor.

Water Pump Problem

Oct/08/2016

The water pump was squealing like a stuck pig! It needed to be rebuilt. We sent it in to “Army Jeep Parts. Inc.” for a complete rebuild. It’s the best way to be sure the pump will fit properly.

* Note: This turned out to be a misdiagnosis.

[See Learning Curve]

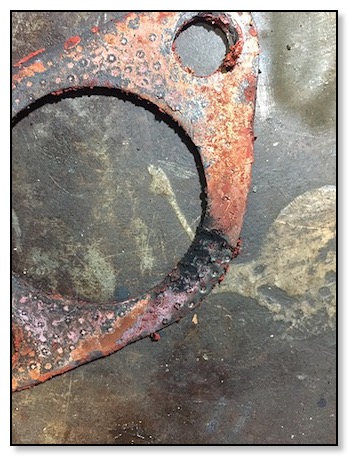

Exhaust Leak

Oct/07/2016

We discovered an exhaust leak where the exhaust pipe joins the manifold. You can see the carbon residue on the gasket.