Don't Always Trust the Web

23/07/15 18:00

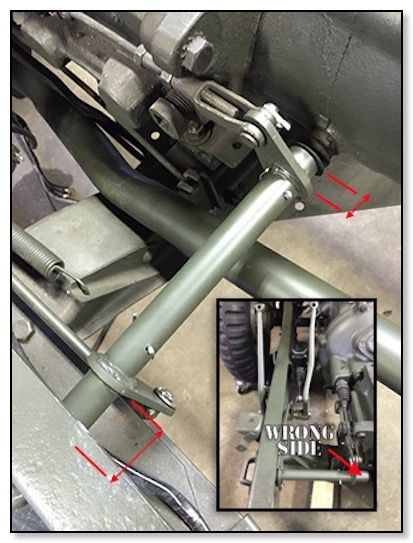

The first time we installed the Clutch Bellcrank Assembly we checked for pictures on the web to see the correct orientation. We found a good picture and installed ours in the same way; wrong! We could tell it didn’t operate smoothly. On further investigation we realized tha it was backwards. The picture we found was wrong. Ironically it was one of the many shots we took of our jeep as we disassembled it! Lesson learned.

Bolt or Clamp Hat Channel

29/06/15 20:00

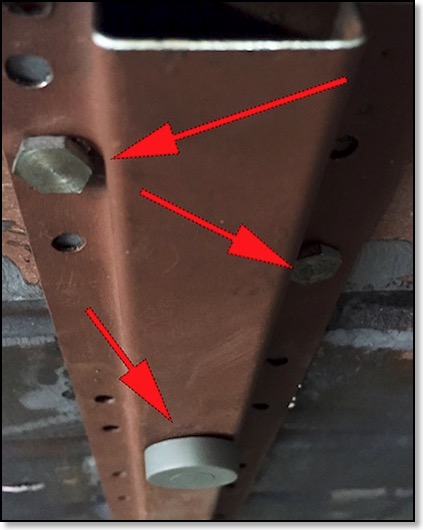

We learned the best way to install the hat channel is to clap or bolt it tight before weldng. This will avoid creating gaps caused by heat warping.

Removing Rusty Bolts

24/07/13 18:00

After destroying a number of nuts and bolts we begin to develop better ways to remove those stubborn rusty bolts. We used the following four methods, sometimes all four on the same bolt!

1. Wire brush exposed threads, tap nut with hammer to loosen rust

2. Apply a solvent. We used PB Blaster, Liquid Wrench or WD-40

3. Heat the nut with a torch to red hot

4. Work the nut back and forth slowly advancing up the threads

Read the small print!

23/07/12 17:00

eBay is a great place to find parts for military jeeps, but you have to be very careful and make sure you’re getting the right part for the right price. We were thrilled to find a Pintle hook for a “buy now” price of only $45. “Click” buy it! Wait, the shipping is $61.00? Oh my gosh, this is from Athens Greece! One month and $106 later a very nice Pintle hook arrived. Lesson learned!

What, no repro?

05/07/12 17:00

We decided to replace the rear crossmember. It had sustained a number of good collisions and showed the battle scars to prove it. After grinding down the rivets and cutting it off, section by section, the old one was removed. While we were at it we thought it would be a good idea to replace the v-brace as well. Ordering a reproduction of the crossmember assembly was easy. Then after an exhaustive search we found out that they do not make a repo of the v-brace for a M38A1! M38, no problem but they don’t fit, we would have to bubba up some shims to make it work. Now here is where some newbie dumb luck comes to play. Just as Ray was starting to remove the v-brace he noticed the time and realized he had to leave. Before he could get back to complete the job we discovered the problem of no easy replacement. With a little straightening and a few welds the original v-brace was back in service!